By ADMIN

Our first priority is to add value to our customers' businesses by offering them only high-quality anti-scale showerheads. This, in turn, enables them to market robust, impeccable merchandise, convey a good corporate image, demonstrate their seriousness and develop sales and turnover.

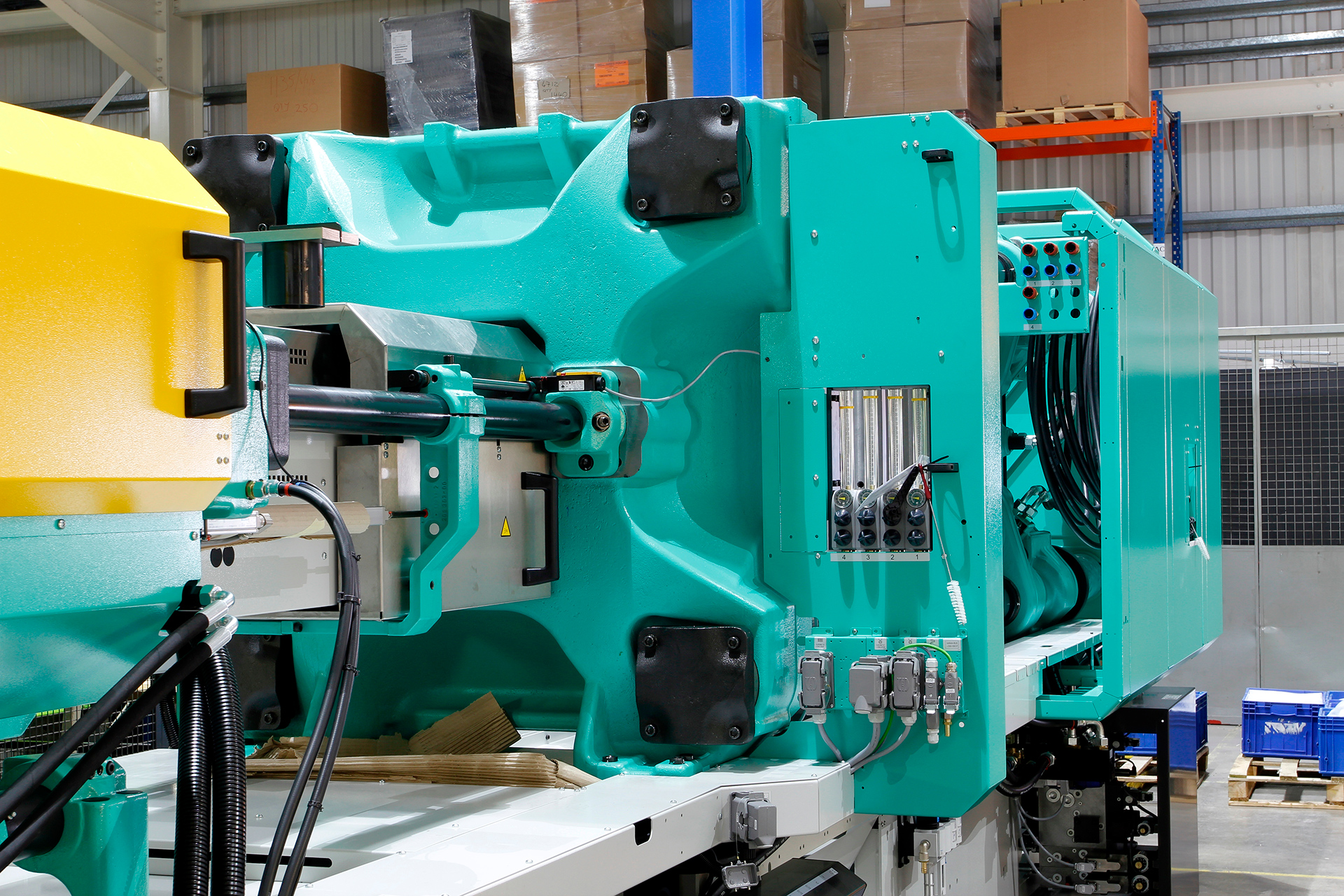

To achieve this, and to ensure the reliability of the products we put on the market, our teams of professionals work closely with top designers and engineers to develop molds for the manufacture of anti-scale showerheads by plastic injection molding. Assisted by state-of-the-art tools, they handle all stages of production, from design to final part, and can produce large quantities.

This has only been possible through re-localization in Europe, since after several decades of offshoring to Asia, we realize that the products obtained may be more attractively priced, but are of inferior quality, harmful to the planet when they don't directly attack our health. Re-localization implies that parts are manufactured in Belgium and that we only work with European suppliers. It uses shorter distribution channels, which are not to be overlooked in these Covid-19 times, and above all enables us to control every step of the way, remaining available, attentive and responsive.

To support our commitment to eco-responsibility, we comply with MEP standards for water-saving processes. Our anti-limescale filtering showerheads feature the Ecosmart system, which limits flow to 9l/min (at 3 bar pressure), reducing water and energy consumption by up to 40%.

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…

For instance, accuracy and efficiency are key to manufacturing. The many critical processes companies…

Belgium is the country that spells chocolate, and connoisseurs across the world agree with the fact…