By ADMIN

For instance, accuracy and efficiency are key to manufacturing. The many critical processes companies depend on as they produce quality plastic parts include one specific one where things stand out, which is the so-called injection molding. Conceivably important, though, is the selection of a dependable injection molding manufacturer in seeking the right partnership. It goes further to discuss what aspects to consider when selecting an injection molding manufacturer, advantages one gets when working with a dedicated plastic injection molding manufacturer, and the general benefits of injection molding in various industries.

Expertise and Experience: A dedicated injection molding maker brings along a wealth of experience and technical know-how.

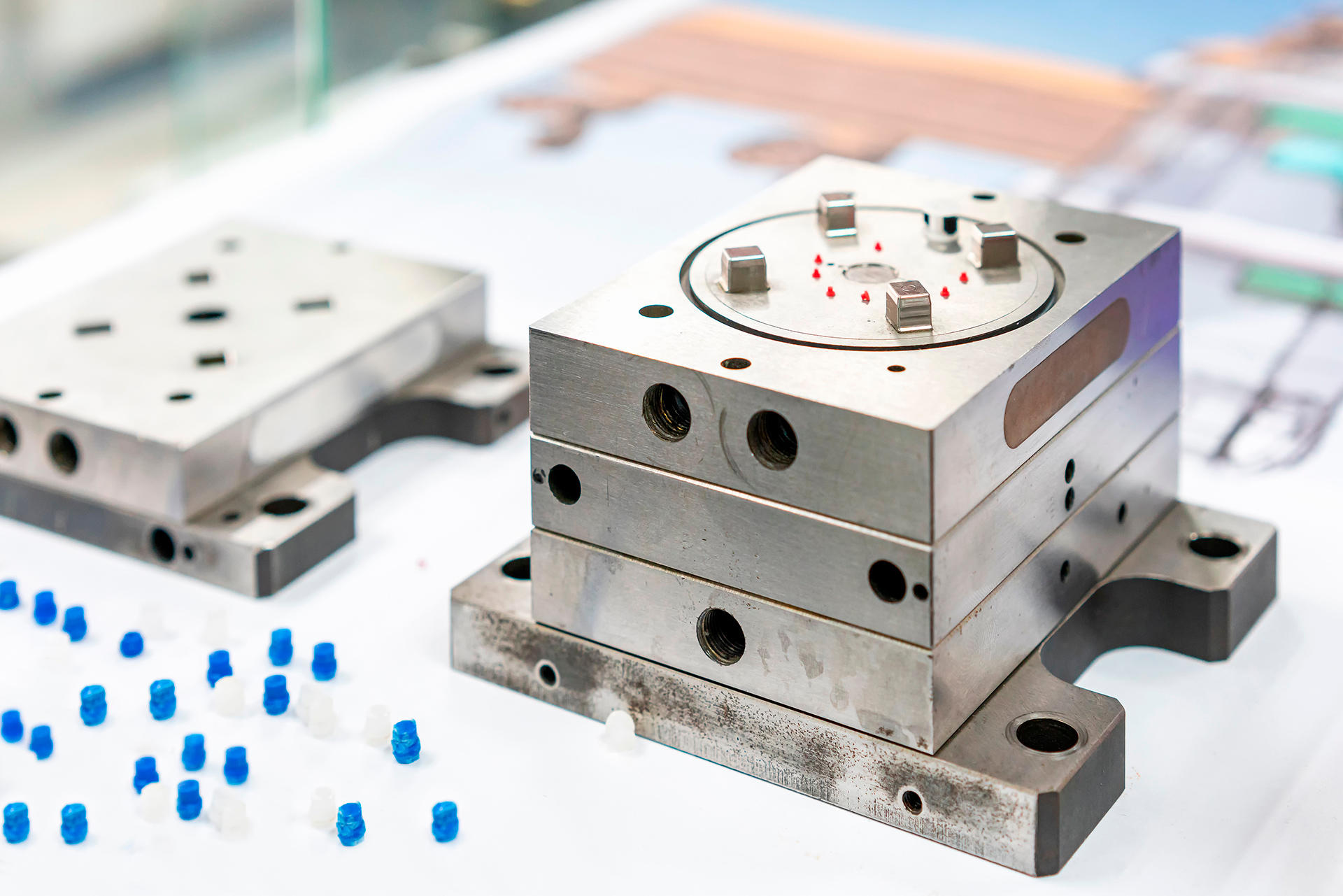

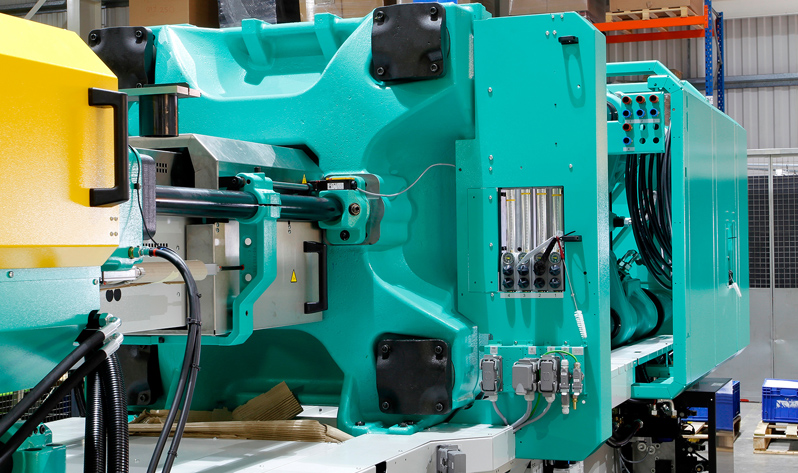

Advanced Technology: The top injection molding manufacturers invest in the latest machinery and technology. These are high-precision molding machines, automated processes, and quality control systems that reduce defects to the minimum degree. Such advancements allow for faster production time and lower costs, making your business more competitive.

It provides customization capabilities. Each business is different. Specialized manufacturers can offer custom solutions. You want custom mold designs, specific materials, or other specific production processes. A professional injection molding maker can fulfill those requirements to differentiate you from the competition in the market.

Cost Efficiency: You should not go for the lowest price as an effective plastic injection molding manufacturer can give you more cost-effective long-run value. They can also assist in making you optimize the designs to be manufactured which in turn will waste minimal material when not necessary and therefore will not increase the cost of production. Sometimes, quality parts equate to fewer return orders and happy customers.

Quality Assurance: A responsible maker of injection molding will possess very good quality control processes. These will involve inspections, assessments to the standards, and material testing. Dealing with a quality-centered maker will ensure that the products meet or exceed the expectations of the customer.

Factors to consider when evaluating a plastic injection molding manufacturer

1. Industry experience

It is a must that the manufacturer has industry-specific experience. Every industry requires something different, and the more experienced the manufacturer in your industry, the better he understands the problems and standards arising in that particular industry.

2. Range of services

Evaluate the service scope of your manufacturer. Some suppliers offer ancillary services like design services, prototyping, and even post-production work such as assembly and packaging. A one-stop shop provider could even help you simplify your supply chain and, in turn, increase efficiency.

3. Material Options

Check on the variety of materials the manufacturer can process. Various applications require specific plastic types, and a flexible injection molding manufacturer should be able to produce multiple kinds of plastics, including thermoplastics, thermosetting plastics, and even biodegradable plastics.

4. Production Ability

Look into their manufacturing capacity. Can they produce high-volume or merely low-volume, small-batch production? This will tell you if you need to engage with a company that can scale up production and sustain it.

5. Customer Service

Excellent customer support forms part of the success factors of a successful partnership. You would want to work with a manufacturer who is responsive and proactive about your concerns. Communication is evident in the design and production phase, as well as after you receive your products.

Injection molding has proven to be of great use in making products during the manufacturing process in numerous industrial sectors. Some examples of how various industries make use of this technology are as follows:

Automobile Industry

A good reason why advanced plastic parts are required in car manufacturing is to enhance fuel efficiency and safety. Injection molding can easily produce an entire range of complex parts used for dashboards, bumpers, and housing. Both the time consumed during production will be reduced along with the weight of vehicles.

Consumer Goods

From household items to electronics, consumer goods highly rely on injection molding. The fact that injection molding enables the production of both aesthetically pleasing designs and functionality makes it ideal for the consumer sector. Manufactured items can be in large volumes, making them available to the market fast, as demand by consumers varies.

Medical Devices

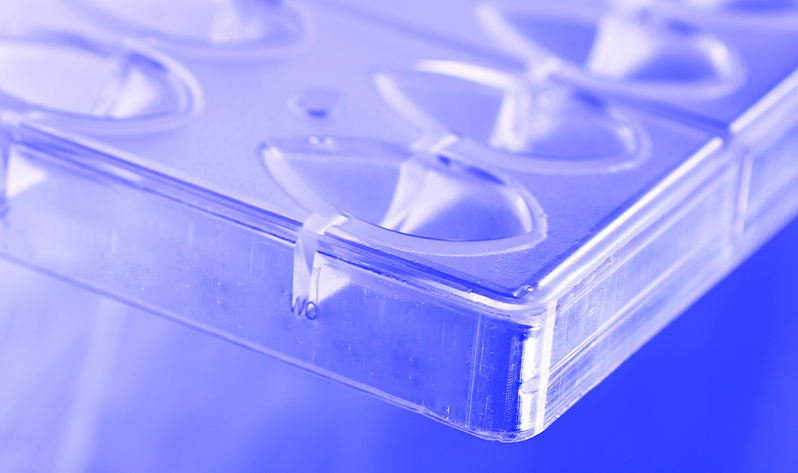

The medical industries have very high regulated standards and need to be precision correct. High-quality medical devices or components like syringes, housings, and connectors are manufactured by injection molding. Cleanliness and compliance form major concerns for these manufacturing manufacturers, and therefore, experience with injection molding becomes crucial.

Electronics

As the speed of technological development is increasing day after day, the electronics industry always tries to come up with innovative solutions. The injection molding process of production helps to create complex parts, such as casings, connectors, and circuit boards, that require precision and reliability. The possibility of working with various materials also contributes towards functionality in electronic devices.

Choosing the right plastic injection molding manufacturer is one of the very good decisions when operating your business. The choice of experienced injection molding maker gives you access to the expertise needed, advanced technology, and more cost-effective solutions tailored to specific needs. As time progresses, industries would change along, and so would the demand for high-quality plastic parts increase; consequently, it would be critical that a reliable injection molding maker can keep up with such rapid change.

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…

Belgium is the country that spells chocolate, and connoisseurs across the world agree with the fact…

Realization of plans, injection moulds in ABS, soft touch finish.