By ADMIN

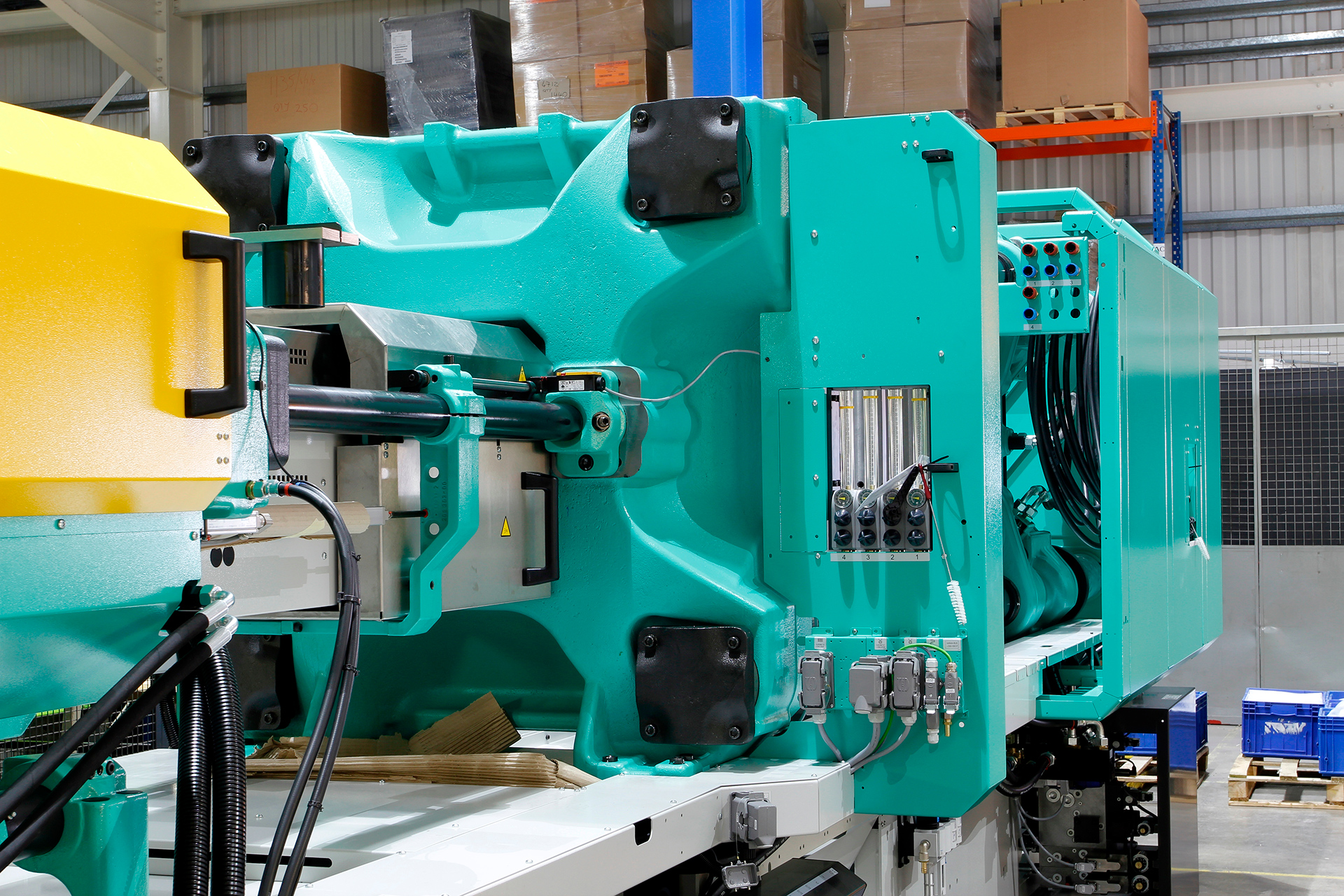

Thermoplastic injection moulds enable mass production of functional objects. The process is applied in many areas, especially for the production of auto parts and household products. Using an injection moulding machine, molten polymers are injected into a mould under high pressure. These polymers, or thermoplastic materials, consist of granules before transformation. The heat softens them and as soon as they are liquid they are injected into the mould, after which they take the right form and then cool and solidify.

One of the major advantages of this method is that it allows duplication of many high-quality objects from the same mould, without the need for further machining. That is why the method is excellent for producing large and even very large series. Thermoplastic injection moulding is not recommended for small series. Silicone casting is better suited for this and also allows for perfect duplication, as well as flexible parts.

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…

For instance, accuracy and efficiency are key to manufacturing. The many critical processes companies…

Belgium is the country that spells chocolate, and connoisseurs across the world agree with the fact…