By ADMIN

What makes Moulding Injection's production quality unique is the combination of competitive advantages that few other industry players can claim. Indeed, beyond the quality of our showerheads produced in Europe (thanks to a strict respect of the standards imposed by the French ACS), it is really our management capabilities that make us suppliers you will want to keep. Our Minral Shower Head project here.

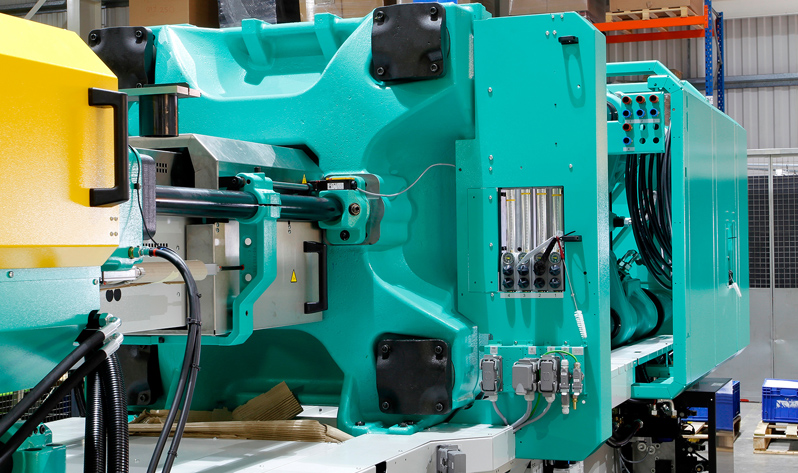

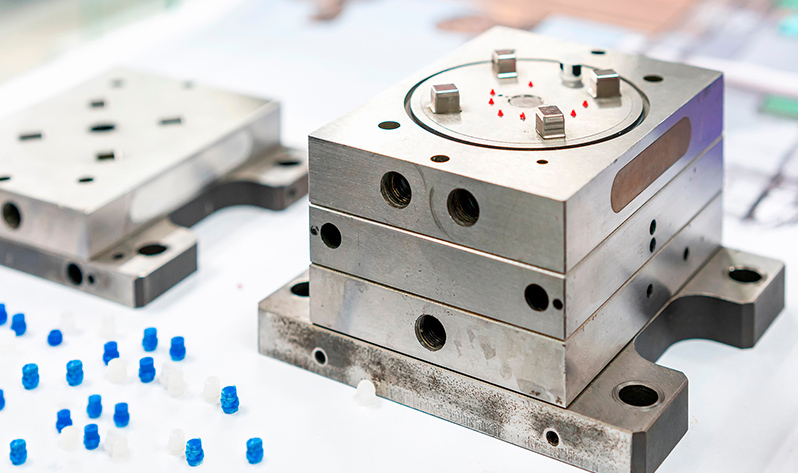

The two key factors of standardisation of plastic injection quality in each of our production units and the sharpest logistical capability of our teams support an incomparably efficient production process.

Moulding Injection's Kanban model for bespoke productivity

How do we produce polycarbonate showers in Europe? Thanks to the intelligent management of our order book and stocks, we are able to produce according to your needs on a "just in time" basis, thus relieving you of the usual commercial pressure that manufacturers usually impose with their sales quotas.

Without pushing you to buy and without forcing you to organise your order according to criteria that your business model does not necessarily benefit from, we have the capacity to adjust our production to demand thanks to a perfectly oiled design and production line for plastic injection moulded parts.

From the creation of the design, through to the optimisation of the manufacturing process and the development of methods perfectly adapted to your specifications by exceptional engineers, we can imagine, design and produce polycarbonate showers on European soil to meet European requirements.

Substantial savings by using a European supplier: relocation of plastic injection in Europe

The resulting speed and quality contrast with the various problems our customers used to encounter before they turned to us. In fact, we spare all the economic players with whom we deal from

The problems of logistical delays that generally go hand in hand with overseas production such as that supplied by Asian service providers;

The ethical difficulties posed by sea and air transport, to the great detriment of our ecological conditions at a time when the climate emergency is emerging;

The additional costs of intermediate travel and storage that the supply chain can add to your product acquisition budget;

The risk of losses caused by extended delivery chains, requiring financial products that put your return on investment in the pockets of insurance companies that you could do without to some extent.

The unnecessary and multiple shipping charges that customs imposes on your showerhead order as it travels.

An EU-stamped shower head manufacturing facility with exceptional sanitary quality

Able to blend into your sanitary landscape, whether French, Belgian or simply European, our production meets the strictest requirements in terms of sanitary index imposed by the European Union.

It is thanks to the efficiency with which we design and market the fruit of our expertise that you can now be offered showerheads of the highest quality and comfort.

Respect for your health: a key feature of our products

By ensuring that each of our production units scrupulously complies with the ACS standards (Attestation de Conformité Sanitaire, which became mandatory for marketing on 24 December 2006), about which the French authorities remain intransigent in observing the precautionary principle, we provide you with products that are perfectly respectful of your health.

By using only materials that have been tested for their absence of effects on human skin, we guarantee that our shower heads are suitable for everyone, including the most sensitive skin.

In general, the ACS standards that our shower equipment complies with give you the assurance that when you come into contact with it, the water you consume will retain all its original properties, a guarantee of quality and health.

But the absolute protection of your physical integrity is only one of the many advantages that characterise our know-how.

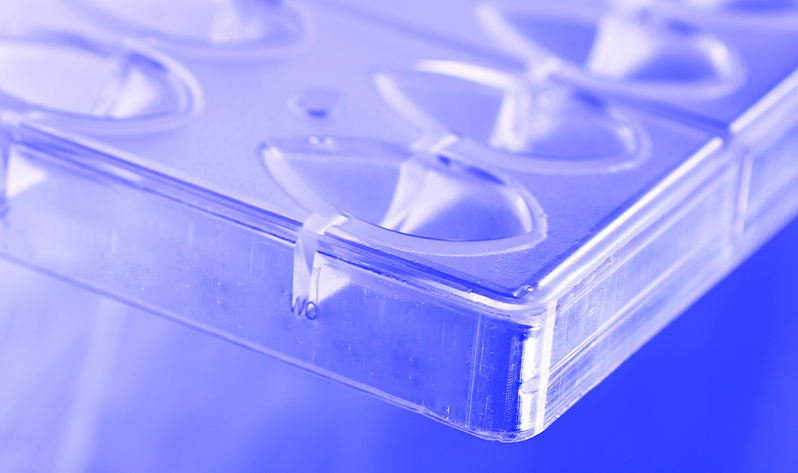

Indeed, the resistance and durability that go hand in hand with each of our creations are made possible by an enlightened choice, made by qualified engineers. The polycarbonate of which our showerheads are made is indeed a material that offers many advantages in this respect, among which

A great lightness (synonymous with good handling at any age and protection against the accidents that can usually cause heavy materials);

Good life expectancy (good resistance to pressure and traction, ensuring long-term use).

Polycarbonate is distinguished from other plastic materials by its high optical purity and impact resistance, making it a material of choice. Approximately 250 times more resistant than glass for the same thickness, this formidable material that will make up your high quality shower heads can even offer additional advantages such as resistance to ultraviolet rays.

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…

For instance, accuracy and efficiency are key to manufacturing. The many critical processes companies…

Belgium is the country that spells chocolate, and connoisseurs across the world agree with the fact…