By ADMIN

Belgium is the country that spells chocolate, and connoisseurs across the world agree with the fact that Belgian chocolatiers have mastered the art of chocolate making, with such rich traditions and exquisite flavors. But that is only half of the story. It's also behind the satisfying making of delicacies because proper packaging of chocolate doesn't let it get stale as well as enhances its appeal. This blog is going to discuss the connection that exists between the chocolates packaged in Belgium and the plastic molds for chocolates alongside other plastic molds used in chocolate making.

One thing is sure about Belgian chocolate: important first impressions. The wrapper is not merely a protective layer; it's an extension of the chocolates themselves. For this country that indulges in artisanal sweets, packaging has to reflect quality and craftsmanship. Even the elegant boxes, colorful wrappers, and even more eco-friendly materials improve the general feel as well as brand identity.

Belgian chocolatiers often like packaging that displays the product yet is practical. Good design packaging may avoid the penetration of moisture and air, which ruin the quality of chocolate inside the package. If chocolates are filled with creams or fruit purees, then tight seals are essential to maintain the freshness of these inner sweets.

Chocolate packaging Belgium is getting a facelift. Sustainability awareness is sweeping the consumer's mind, and chocolatiers are increasingly moving towards eco-friendly packaging solutions. Innovations in biodegradable and recyclable solutions can enable brands to appeal to increasingly conscious consumers about the environment.

Another other benefit entails personalization of packaging. Chocolatiers are now innovating with special designs for the clients to identify with them, thereby making packaging a point of uniqueness. This not only improves the unboxing experience but also inspires a client to share their chocolate indulgence on social media to get more clients.

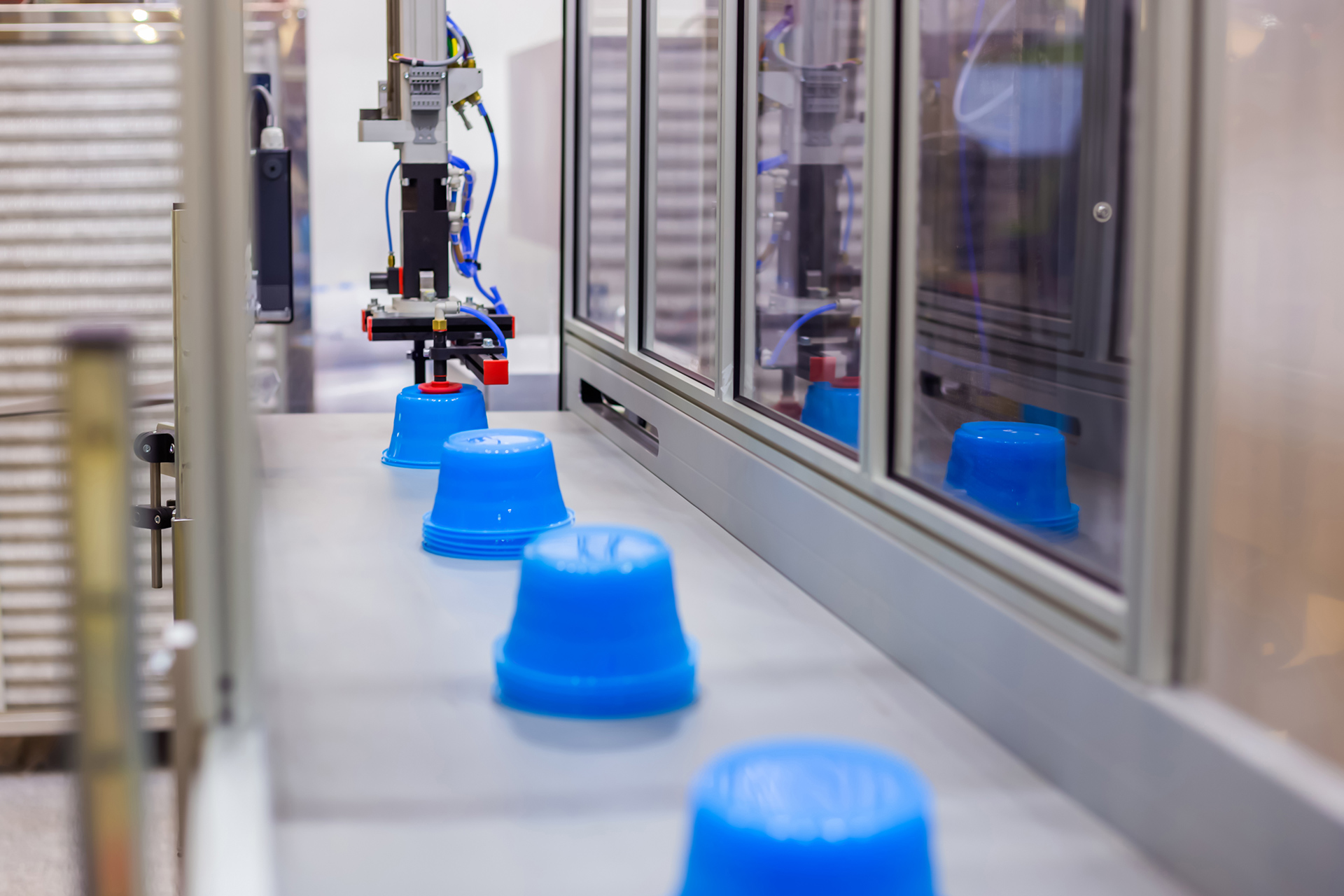

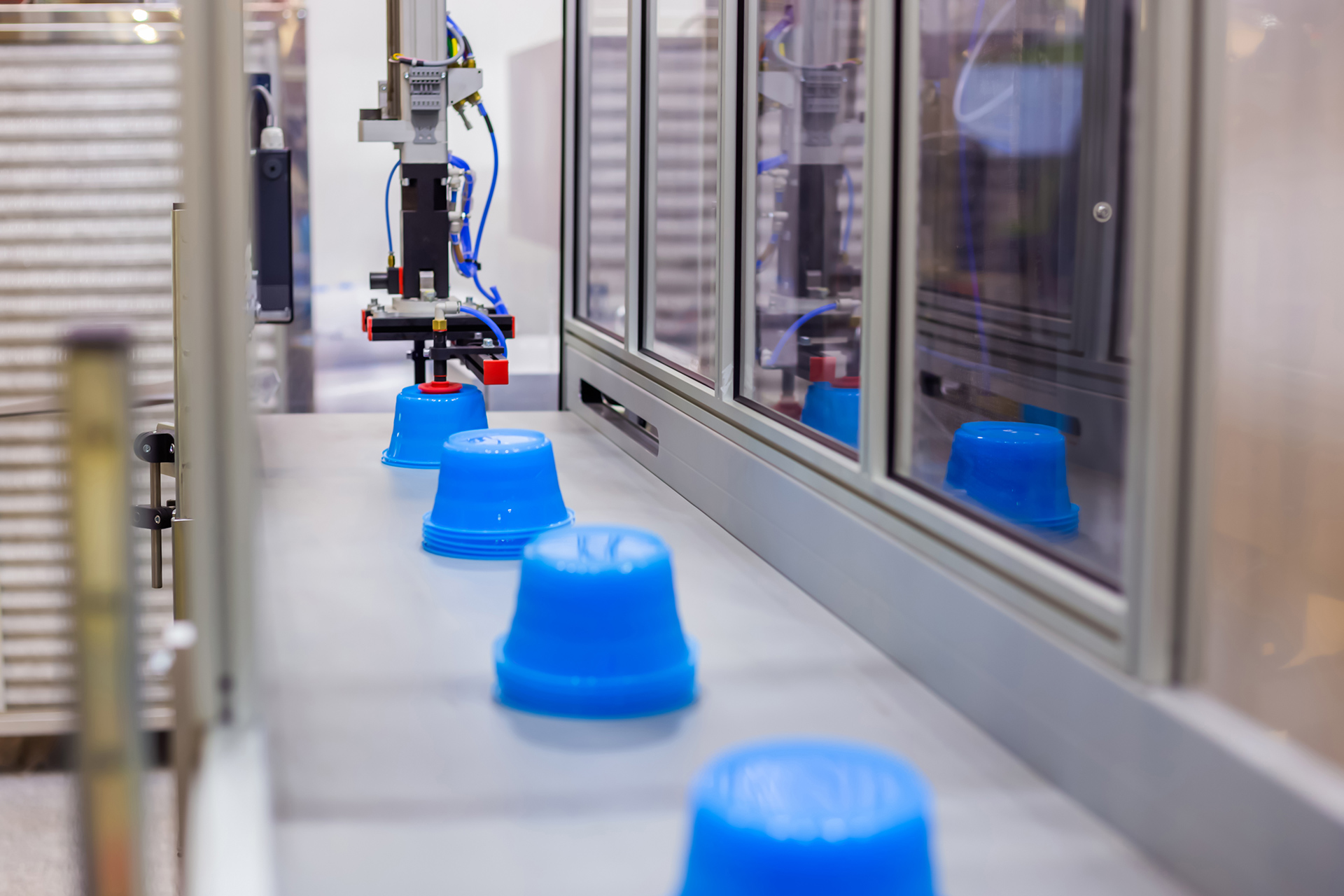

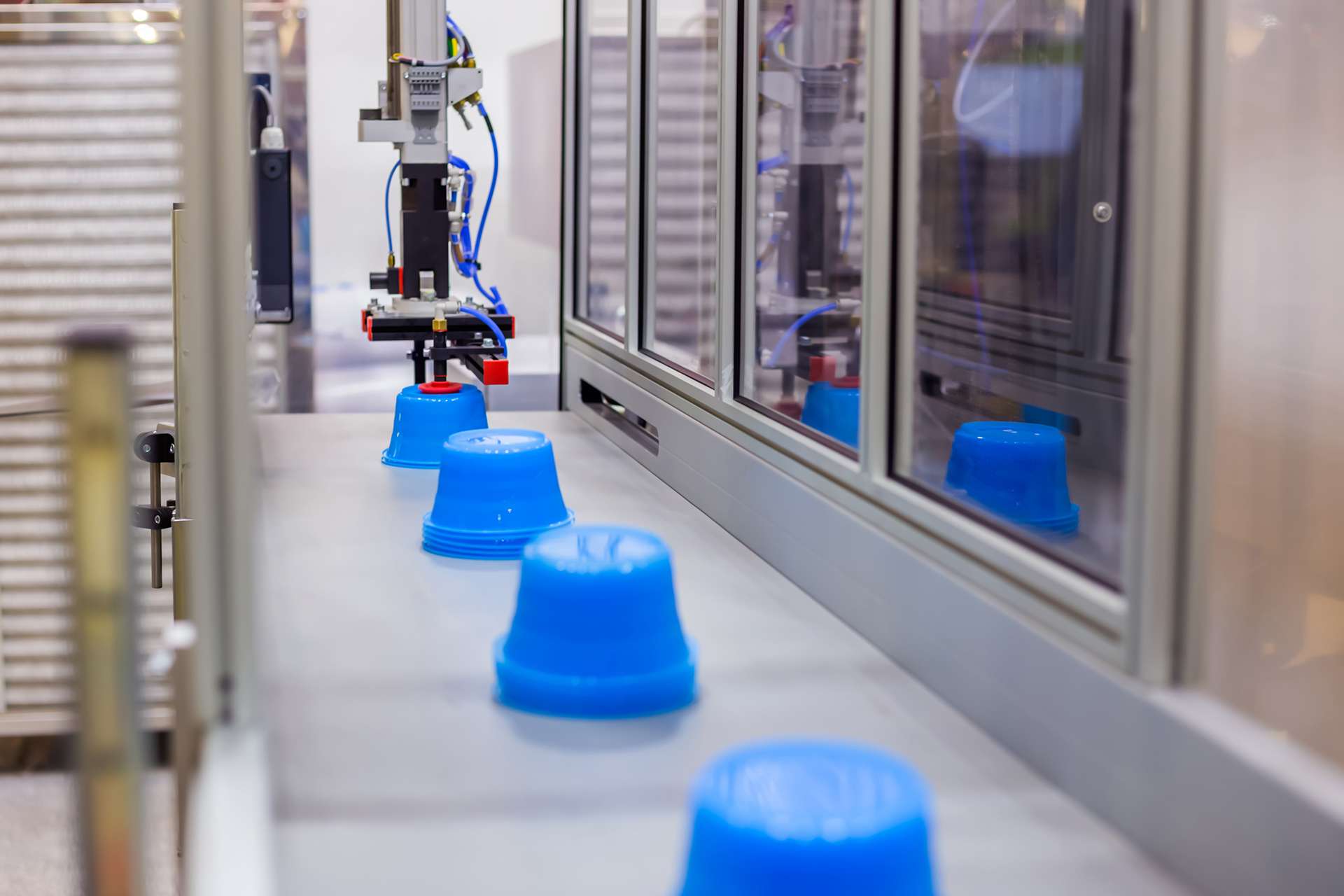

Plastic chocolate molds are a game changer for the world of chocolate making. Flexible; this tool is meant to help chocolatiers, who have a plethora of shapes and designs by virtue of working with them, as opposed to producing the aforementioned with age-old methods. Perhaps this does not mean only classic truffles or seasonal shapes but bespoke pieces found in the production process-all very specific devices that make precision less possible than with the age-old methods.

Another benefit of plastic molds is that they do not warp or break down like silicone or metal molds after repeated use. They are easy to clean and reuse. The plastic molds are perfect for any chocolatier due to the non-costly nature of the molds.

Style variation: Plastic molds for chocolate making can be procured in almost any shape and size, ranging from the classic bonbons to holiday-themed shapes. This variety allows chocolatiers to experiment and innovate, thus designing one-of-a-kind products that can be truly competitive in a market where competition keeps on increasing.

Ease of Use: The plastic molds have an easy release of chocolates, unlike their ancient counterparts. This feature ensures that breakage risk is minimized so that each piece will be beautifully formed and ready for the bagging phase.

Cost-Effectiveness: Though purchasing good plastic molds is expensive, the long life and reusable quality give business a keen opportunity to reap in benefits. With care, these molds can be in use for years, and the chocolatier can reap his or her returns.

Consistency: Plastic molds are ideal for chocolatiers who want to manufacture chocolates in masses. Every time the chocolates get poured into plastic molds, there is the guarantee of a homogenous result. This is crucial in the issue of quality and satisfaction of customers.

Key Considerations in Selecting Plastic Molds for Chocolate

There is much to consider when selecting plastic molds for chocolate making. The types of plastics used for the manufacture of molds are therefore first and foremost in the consideration list, one being food grade quality. High-quality molds will not just produce better chocolates but will also ensure that they are safer to consume.

When it comes to design, consider the types of chocolates that you want to come up with, whether or not they are aligned to your brand identity and target audience.

Size: These will depend on the size of the suitable mold for your production. The large, more massive molds are more appropriate for high volume production while the small ones can be more creative and custom.

Ease of Cleaning: Easy-to-clean molds should be selected. As this saves time in the production process, hygiene standards are maintained.

Chocolatiers instead have found new and creative ways to use plastic molds instead of traditional chocolates. For instance, the chocolate sculptures and decorative elements for cakes and unique party favors. This opens an infinite number of possibilities for professional chocolatiers and amateur enthusiasts alike.

Furthermore, the preferences of many chocolatiers are incorporating flavors and ingredients that are more modernized with contemporary tastes. This includes gourmet fillings, infused chocolates, and even savory options. Therefore, with the creative ability presented by plastic molds, possibilities with chocolate making seem endless.

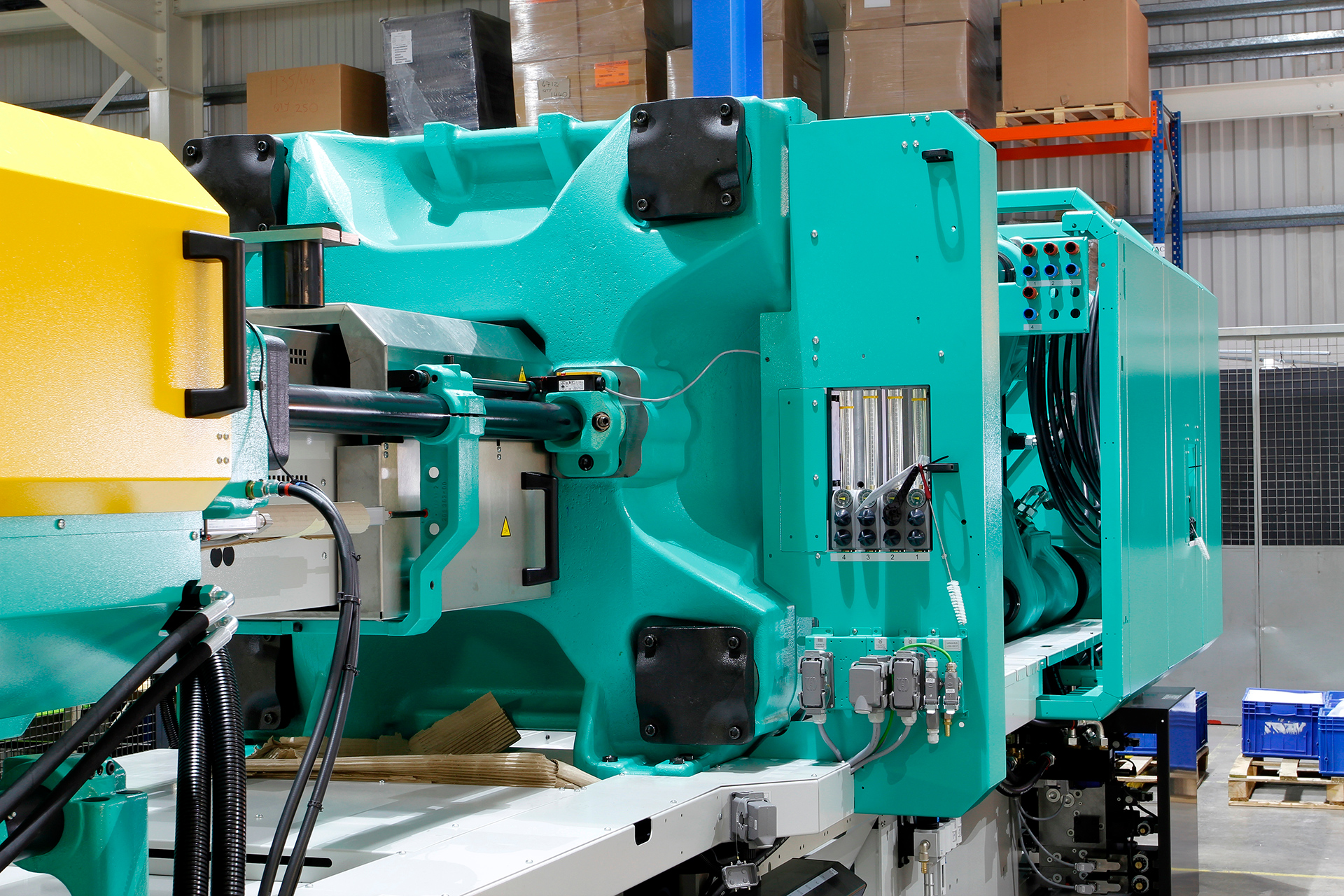

Therefore, integrating technology in making both chocolate packaging and molds will expect to take the industry further into the future. This includes 3D printing and advanced materials that will catapult the creativity and efficiency at which chocolatiers work.

Finally, sustainability should be focused on and will surely be the key to innovative packaging solutions. As consumers grow more precise and demanding, requiring products that are not only environmentally friendly but also pleasing and aesthetic, people will be asking for packages that are satisfying both their senses of eco-friendliness and aesthetic value. It will push the chocolatier to explore new materials and designs that will resonate with the concept of eco-friendliness.

In Belgium, chocolate packaging is far more than a protective cover. More than that, the integrational element of the whole chocolate experience, indeed, comes first. The really new solution within plastic chocolate molds and eco-friendly packaging possibilities promises to upgrade the whole range of goods while satisfying consumerism at its best. Those players who take this naturally for them in the future, it will be hard for them not to thrive well as well in this sweet landscape. Whether you are a professional chocolate maker or an enthusiastic home baker, the importance of both packaging and molds will greatly increase your journey to becoming a chocolatier.

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…

For instance, accuracy and efficiency are key to manufacturing. The many critical processes companies…

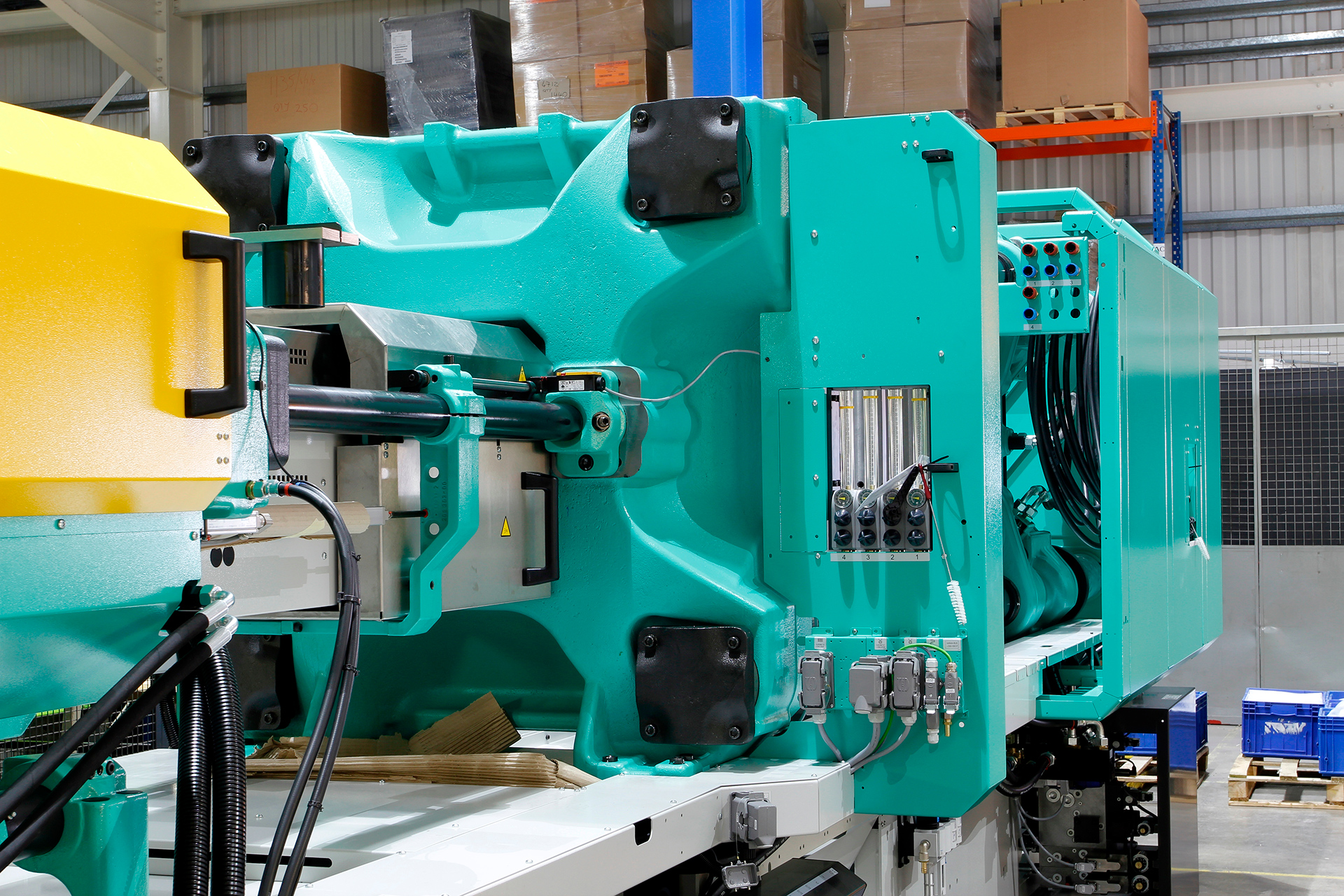

Realization of plans, injection moulds in ABS, soft touch finish.